Combicore cores: Innovative Benefits

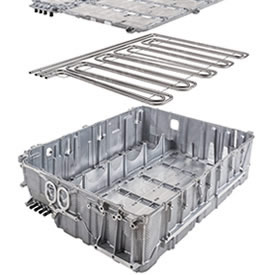

Channels are realized in cast parts with Combicore. Typical automotive applications are heat sinks, cooling plates, battery housings, DC / DC converters, electric motors, ...

As an innovation, Combicore cores and components from our customers have received multiple awards. Combicore properties offer decisive success criteria:

- Realization of complex channel structures

"in one pour" - Dimensionally stable at over 1200 bar

- Ideal for high pressure die casting (HPDC),

can be used in all casting processes - Great freedom of design

- Optimal temperature control of components

(Cooling + heating) - Leak-free,

no drilling and no plugs required - Reduction of material, efficient lightweight construction

- Sustainable conservation of resources, also in later operation

- Easy removal of the filling after the casting process

- Inexpensive

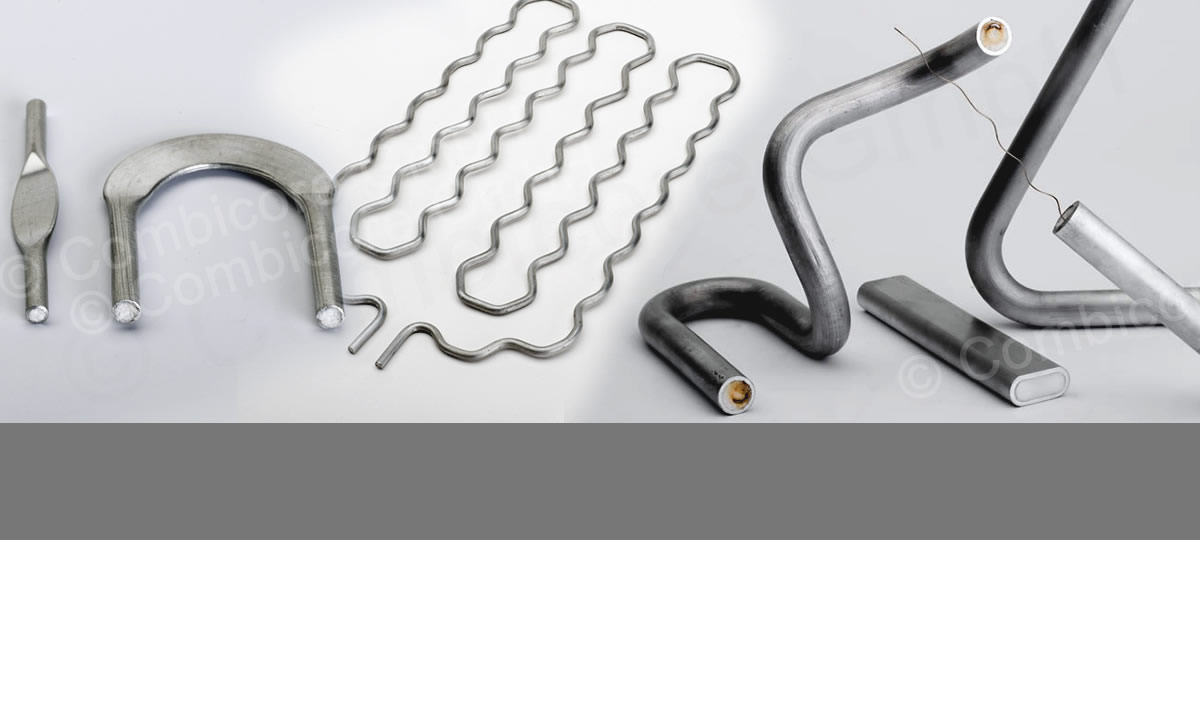

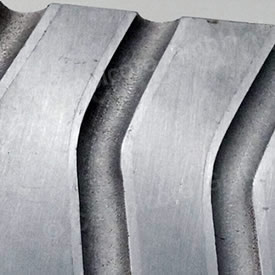

Metal Forming:

Tube, wire, sheet metal

As a metalworker, we have several 2D and 3D CNC bending machines with which we can also create complex tube geometries. We process materials such as steel, stainless steel and non-ferrous metals.

A wide variety of shapes can be created with tube end forming technology, so that tubes can be connected to the system without leakages. Expensive turned parts or complex welding and soldering work can thus be saved.

We also carry out the following work for you:

- Sawing

- Deburring

- Pressing

- Drilling

- Turning

- Milling

- Annealing / heat treatment

- Welding

- Soldering

Which component can we shape for you?

Assemblies:

Strong connections

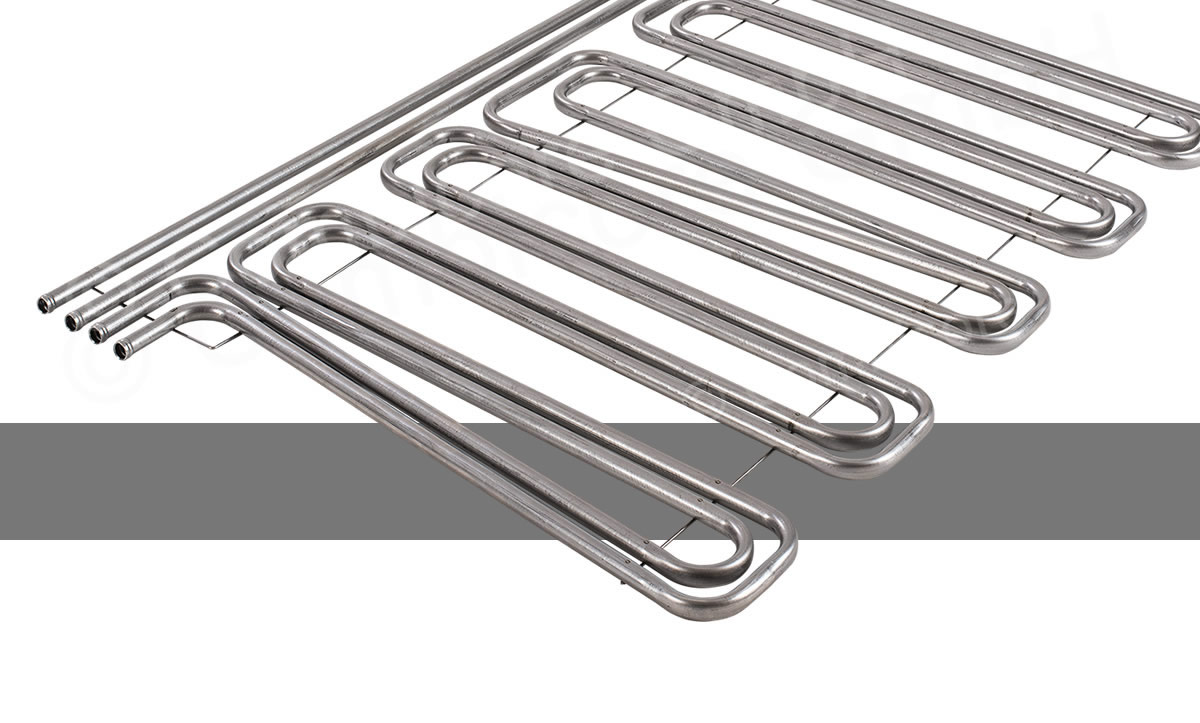

We assemble bent tubes and profiles into ready-to-assemble end products. Several Combicore cores can also be connected to core packages by welding, soldering or other suitable joining processes.

Attached wire bridges, pins and other attachments can facilitate handling in the foundry.

Inquire about your options.

We are happy to help.

Cores for high pressure die casting and other casting processes

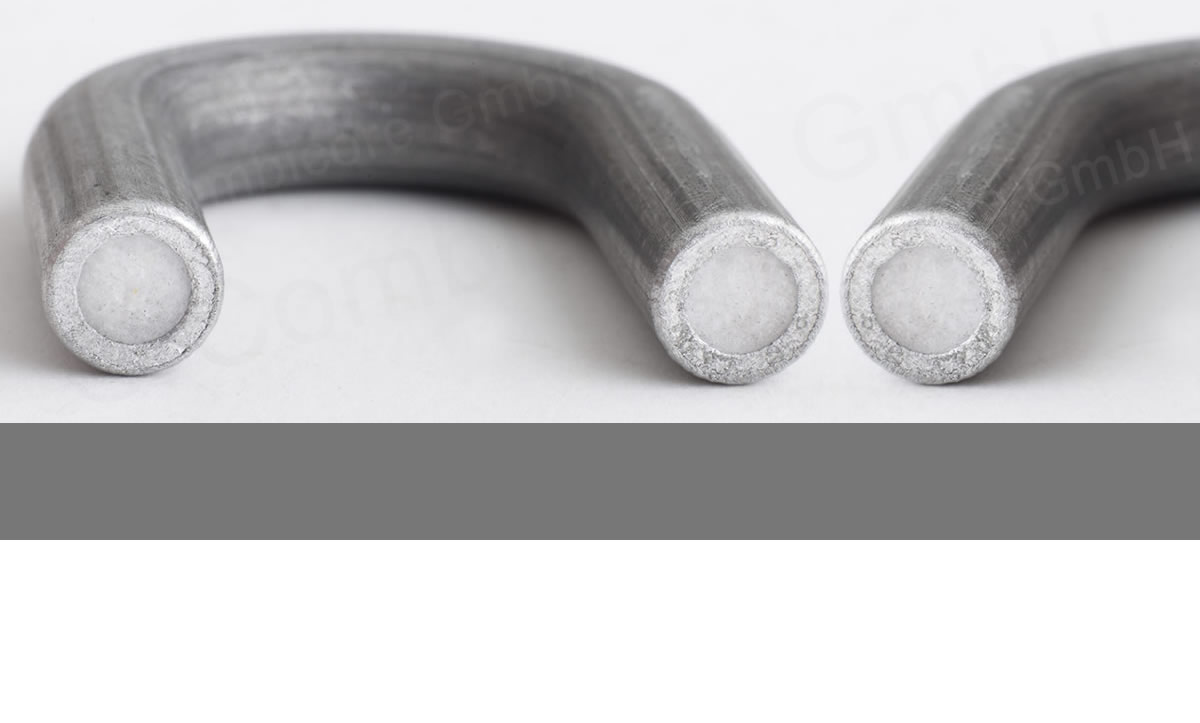

Combicore cores consist of a shaped metal shell that is filled with a special material. This enables foundries to create media-carrying channels and other cavities in cast parts, efficiently, quickly, reliably and cost-effectively.

Combicore cores are extremely stable and can also be used in high pressure die casting with over 1200 bar. After the casting process, the filling is removed. The metal shell remains as a channel in the component.

| Alloys: | AlMn1 / EN AW 3103, AlMgSi0,5 / EN AW 6060, Al99,5 / EN AW 1050, CW021A / CU-HCP / 2.0070, CW024A / CU-DHP / 2.0090, E195, E235, 1.4301, etc. |

| Channel-Ø: | from 0,5 mm |

| Wall thickness tube: | from 0,5 mm |

| Channel length: | several meters possible |

The Combicore technology creates highly efficient cooling channels, which ensure optimal temperature control of the near-net-shape cast part. Lubrication channels are also typical applications in the automotive sector.

With Combicore, casting cores are used in high pressure die casting for the first time.

Trust in our decades of experience.

Application examples: Combicore cores and media-carrying channels

Know-how and Services

Consulting and Engineering

We offer our customers customized solutions and are at your side already in the construction phase.

In dialogue we determine application-specific requirements for our Combicore casting cores. Our engineers define the individual optimal core parameters for components, according to cost-effecient production.

If required, we can also support you with casting-related issues and core removal.

Other metal shaped parts and assemblies meet the desired requirements. If you are looking for quality, you are right with us.

Added value: Made in Germany

Combicore is your excellent supplier for formed metal articles. Customer satisfaction is our top priority. In accordance with customer specifications, we undertake to provide exceptional quality products with the lowest possible environmental and safety risks.

Quality and the environment

Combicore cores meet today's requirements of modern foundry technology and satisfy modern, ecological and economic conditions.

We manufacture samples, prototypes, small and large series for customers in the division ...

- Automotive,

- Electronics,

- Furniture,

- White goods,

- ...

Awards, recognitions and prizes

In recent years, the Combicore technology has received several awards and has been recognized as innovative and particularly sustainable. We present a small selection of our most important "achievements" here.

Industry award

Combicore has been awarded the industry prize four times in a row. We are Best of in the categories Automotive and supplier. Our innovative core solution for foundries convinced the top-class jury of experts. Our technology is of very high technical, economic, ecological and social benefit.

We see the award as confirmation of our conviction that we work in a solution-oriented manner and thus meet the demands of our customers, namely to always be one step ahead.

We have not participated since award winners were asked to plan an advertising budget.

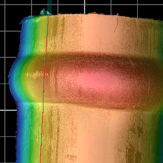

International High Pressure Die Casting Contest

The heat sink for a cooling plate in hybrid technology from the Moneva foundry received special recognition. The jury from research and science praised the strong innovative strength and high demands in casting technology.

The die-cast insert is an important pioneer for the use of hybrid drives, according to the jury. Sophisticated cooling technology solves problems in battery technology. The product-safe cast aluminum cooling tube in a secondary aluminum alloy is important for the recognition. The substitution of the multi-part sheet metal construction leads to significant cost savings.

The heat sink accommodates the lithium-ion cells and ensures that the temperature of the battery pack is even.

That was in 2012. We are particularly proud of this award and with this application we were among the first automotive suppliers for new technologies in electromobility.

Innovation Champion & material efficiency award

The German Material Efficiency Prize was awarded to us by the Federal Ministry of Economics and Technology (BMWi) in Berlin in 2010. Since then we have continuously developed our technology. Even then, people recognized our creative and innovative ideas in the field of foundry technology.

"Those who produce efficiently win!" Emphasized Jochen Homann, State Secretary in the BMWi. Material efficiency pays off after a short time. With intelligent solutions, raw and operational materials can be saved in the long term. "That creates clear competitive advantages," says Homann.

In the same year we prevailed against 420 applicants from 23 countries and were named Innovation Champion by the Network of Automotive Excellence (NoAE).

Address:

Combicore GmbH

Am Hühnerbusch 10

D-67688 Rodenbach

Phone: +49 (0)6301 / 38295-70

info [ @ ] combicore.com