Combicore - cores for HPDC and other processes

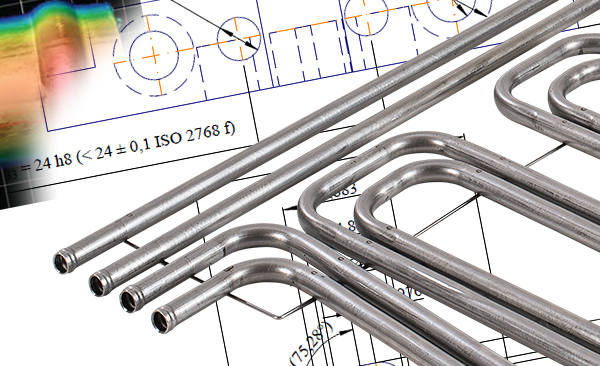

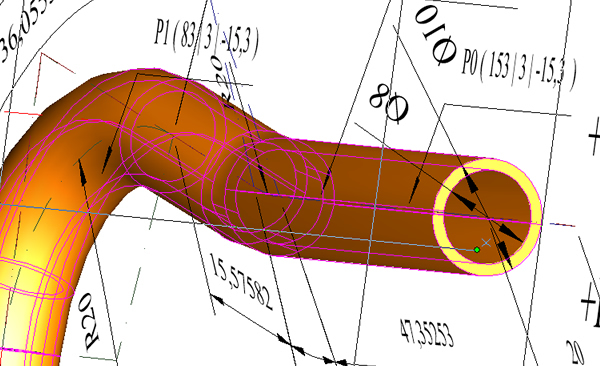

Combicore cores consist of a shaped metal shell that is filled with a special material. This enables foundries to create media-carrying channels and other cavities in cast parts, efficiently, quickly, reliably and cost-effectively.

Combicore cores are extremely stable and can also be used in high pressure die casting with over 1200 bar.

After the casting process, the filling is removed. The metal shell remains as a channel in the component.

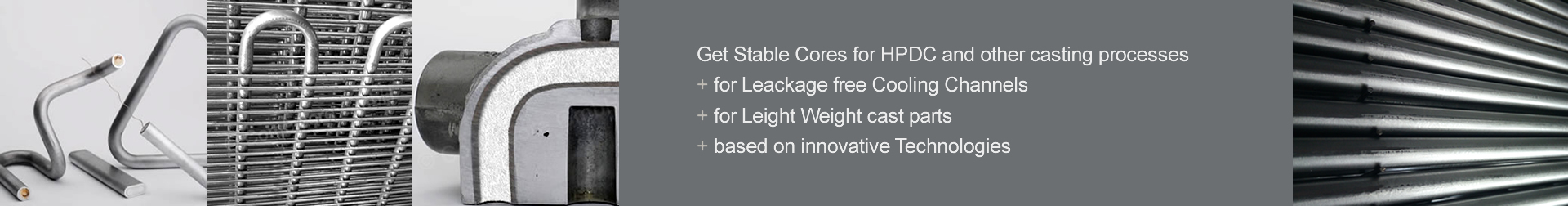

We developed an innovative heat exchanger based on the Combicore technology to achieve an extremely efficient cooling effect in small spaces. At the same time, the pressure loss in the created channel is very low.

Get in touch now!